What is exterior aluminum cladding?

In recent years, with the development of the construction industry and the advancement of technology, the types and usage methods of exterior wall materials have been continuously enriched. As a new type of building material, exterior aluminum cladding is increasingly favored by architects, developers and homeowners. So, what is exterior aluminum cladding? What are its characteristics and advantages? This article will explore this issue in detail.

Definition of exterior aluminum cladding

Exterior aluminum cladding, as the name suggests, refers to an exterior decorative material that covers a layer of aluminum on the surface of the exterior wall of a building. Aluminum cladding is usually made of aluminum plates, aluminum alloys and other materials. After special treatment, it forms an exterior wall material with multiple functions such as waterproofing, heat preservation, heat insulation, and corrosion resistance. Aluminum cladding can not only enhance the aesthetics of the building, but also effectively extend the service life of the building.

Composition structure of exterior aluminum cladding

Generally speaking, exterior aluminum cladding consists of multiple parts, mainly including aluminum plate layer, insulation layer, waterproof layer and fixed structure.

Aluminum plate layer: This is the core part of the exterior aluminum cladding. It usually uses high-strength aluminum alloy plates and is processed by anodizing, electrophoretic coating, fluorocarbon spraying and other processes to improve the corrosion resistance and aesthetics of aluminum.

Insulation layer: In order to improve the thermal insulation performance of the building, a layer of thermal insulation materials such as polyurethane and polystyrene is usually sandwiched in the aluminum cladding. This layer of material can effectively reduce heat loss and improve the energy efficiency of the building.

Waterproof layer: The waterproof layer design of the aluminum cladding is very important. Usually, a polymer waterproof membrane or waterproof coating is used to ensure that the exterior wall can be effectively waterproof under severe weather conditions and prevent rainwater from penetrating into the interior of the building.

Fixed structure: The exterior aluminum cladding is installed on the exterior wall of the building through a specially designed fixed structure. Aluminum alloy keels or stainless steel brackets are usually used to fix the aluminum plate, and special fasteners are used to ensure the firmness and durability of the aluminum cladding.

Construction process of exterior aluminum cladding

The construction of exterior aluminum cladding is a complex project that requires multiple processes to ensure that the final effect meets the design requirements. Generally, the construction process includes the following steps:

Design and planning: Before construction, the architect needs to develop a detailed aluminum cladding design plan based on the structural characteristics and appearance requirements of the building, including the size, color, and surface treatment of the aluminum plate.

Material preparation: According to the design plan, select suitable aluminum alloy plates and other auxiliary materials, and process the materials, such as cutting, punching, and folding, to facilitate subsequent installation.

Wall treatment: Before installing the aluminum cladding, the exterior wall surface of the building needs to be processed, such as cleaning, leveling, and priming, to ensure that the exterior wall is flat and clean for the installation of the aluminum cladding.

Installation of aluminum alloy keels: Install aluminum alloy keels or stainless steel brackets on the exterior wall, which is the basic structure for the installation of aluminum cladding. The installation of the keel requires precise positioning to ensure its horizontality and verticality to ensure the flatness and firmness of the aluminum cladding.

Installation of aluminum plates: Install the processed aluminum plates on the keels one by one according to the design drawings. There is usually a certain gap between the aluminum plates to avoid deformation caused by thermal expansion and contraction. The gaps are usually filled with waterproof sealant to enhance the waterproof performance.

Inspection and acceptance: After the installation of aluminum cladding is completed, strict inspection is required to ensure that the aluminum plate is firmly installed, the surface is flat, the color is uniform, and all performance indicators meet the design requirements. After the acceptance is passed, the construction of the exterior wall aluminum cladding can be considered completed.

Advantages of exterior wall aluminum cladding

The reason why exterior wall aluminum cladding is widely used is mainly due to its following significant advantages:

Strong corrosion resistance: Aluminum itself has strong corrosion resistance, especially aluminum plates that have been anodized or fluorocarbon sprayed, which can maintain good performance for a long time in outdoor environments and resist wind and rain erosion.

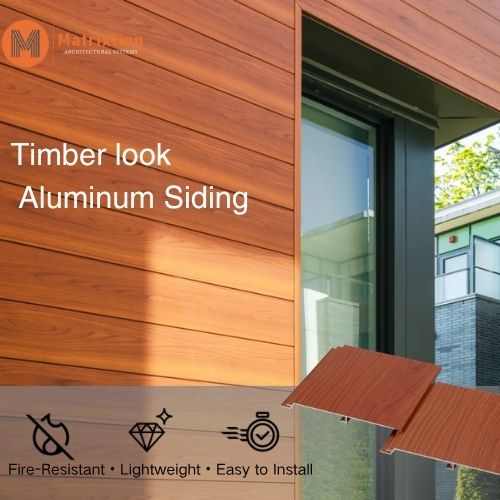

Light weight and high strength: The aluminum plate of aluminum cladding is light in weight but high in strength, which not only reduces the load-bearing pressure of the building, but also has good impact resistance.

Aesthetics and diversity: The surface treatment process of aluminum plates is diverse and the color selection is rich. Various decorative effects can be achieved according to design requirements to enhance the appearance of the building.

Convenient construction: Compared with traditional exterior wall materials, the installation of aluminum cladding is simpler and faster, and large-scale construction can be completed in a short time, effectively shortening the construction period.

Recyclable: Aluminum has good recyclability, and waste aluminum plates can be recycled and reused, which meets environmental protection requirements and helps reduce resource waste.

Excellent fire resistance: Aluminum itself is non-combustible, and the insulation materials and waterproof layers used in aluminum cladding usually have good fire resistance, so aluminum cladding performs well in building fire safety.

Conclusion

As a new type of building material, exterior wall aluminum cladding is gradually becoming the mainstream choice of modern building exterior wall materials due to its superior performance and wide application. It not only provides solid protection for buildings, but also gives buildings unique aesthetic value. As people's requirements for building quality continue to increase, exterior wall aluminum cladding will be used in more construction projects.